Revitalization of power transformers insulation

This the most comprehensive technology for water and all oxidation products removal

from power transformers oil-cellulose insulation system. It is performed on-site

and online without transformer operation interruption.

Process of revitalization includes the following:

» REGENERATION OF TRANSFORMER OIL

» DEPTH PURIFICATION FROM DEGRADATION PRODUCTS AND DRYING OF CELLULOSE INSULATION

Guaranteed insulation characteristics after the treatment and within warranty period

of minimum twelve months

» tgδ of total insulation

» Insulation resistance

» Water content in solid insulation

» tgδ of insulating oil

» Neutralization/Acid number

» Interfacial tension

» Dielectric strength

» Water content in insulating oil

» Particles

Operation principle

Water and all aging products are polar compounds. Revitalization is based on adsorption

of all polar compounds from total insulation by creating continuous dynamic non-equilibrium

(disbalance) of their content between solid and liquid insulation.

Polar compounds constantly migrate (diffusion process) from paper to oil, where from

they are adsorbed by synthetic adsorbents, i.e. removed from insulation.

This is achieved by producing/creating continuous dynamic non-equilibrium.

Temperature increase stimulates diffusion process and therefore migration of polar

compounds from paper to oil is more intense.

Long lasting results

Apart from above mentioned solid insulation characteristics (tgδ, water content,

insulation resistance) proof of solid insulation depth purification and dehydration

is long-term stability of insulating oil characteristics.

Twelve months of transformer operation is generally long enough period for potentially

remained water and oxidation products in solid insulation to degrade characteristics

of insulating oil.

As a proof of successfully implemented depth purification and dehydration of solid

insulation we usually guarantee that oil characteristics within twelve month will

not exceeded limits defined in specification IEC 60422, Table 3.

Insulation revitalization significantly extends power transformer lifetime and increases

operation reliability on the network.

In comparison with technologies available nowadays, oil-cellulose revitalization

methods using synthetic adsorbents have shown significantly better results, providing

essential changes in electro energetic equipment maintenance approach, primarily

in maintenance of oil-cellulose insulating systems in power transformers.

Goals and results of oil-cellulose insulating system revitalization

Revitalization technology has been applied and effects of oil-cellulose insulating

system revitalization have been proved on more than 100 power transformers. Optimal

characteristics of adsorbents, obtained in more than twenty years of research and

exploitation, have been confirmed by achieved results.

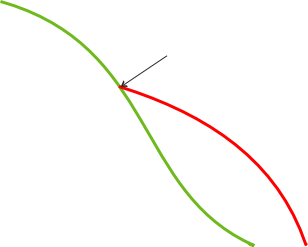

Following diagram shows aging curves of revitalized (red) and not revitalized (blue)

power transformers insulation system. Prolongation of power transformer lifetime

after total insulation revitalization is obvious.

Depending on insulation condition and revitalization treatment timing power transformer

lifetime could be significantly increased- from 10 to 35 years and more.

Transformer insulation revitalization process main characteristics

» No oil heating

» No oil vacuuming

» No transformer vacuuming

» New oil not required (saving resources)

» Long lasting effects on complete insulation system

» Increased transformer operation reliability on the network

» Extended transformer lifetime

» No loss of production (can be performed while transformer is energized)

» Cost effective

» Ecology friendly (zero gas emission and no disposal of waste oil)

» Transformer washing not required

» No exposing of transformer core to atmosphere

» Low energy consumption

» Reactivation of synthetic adsorbents for few hundred times

» Simple machinery construction

» Simple handling

» Easy installation

» Minimum supervision

» Field operation in all weather conditions

» Minimal power consumption (0.5-3 kW)

» Guaranteed results for long period of time